PRODUCT

Product Portfolio

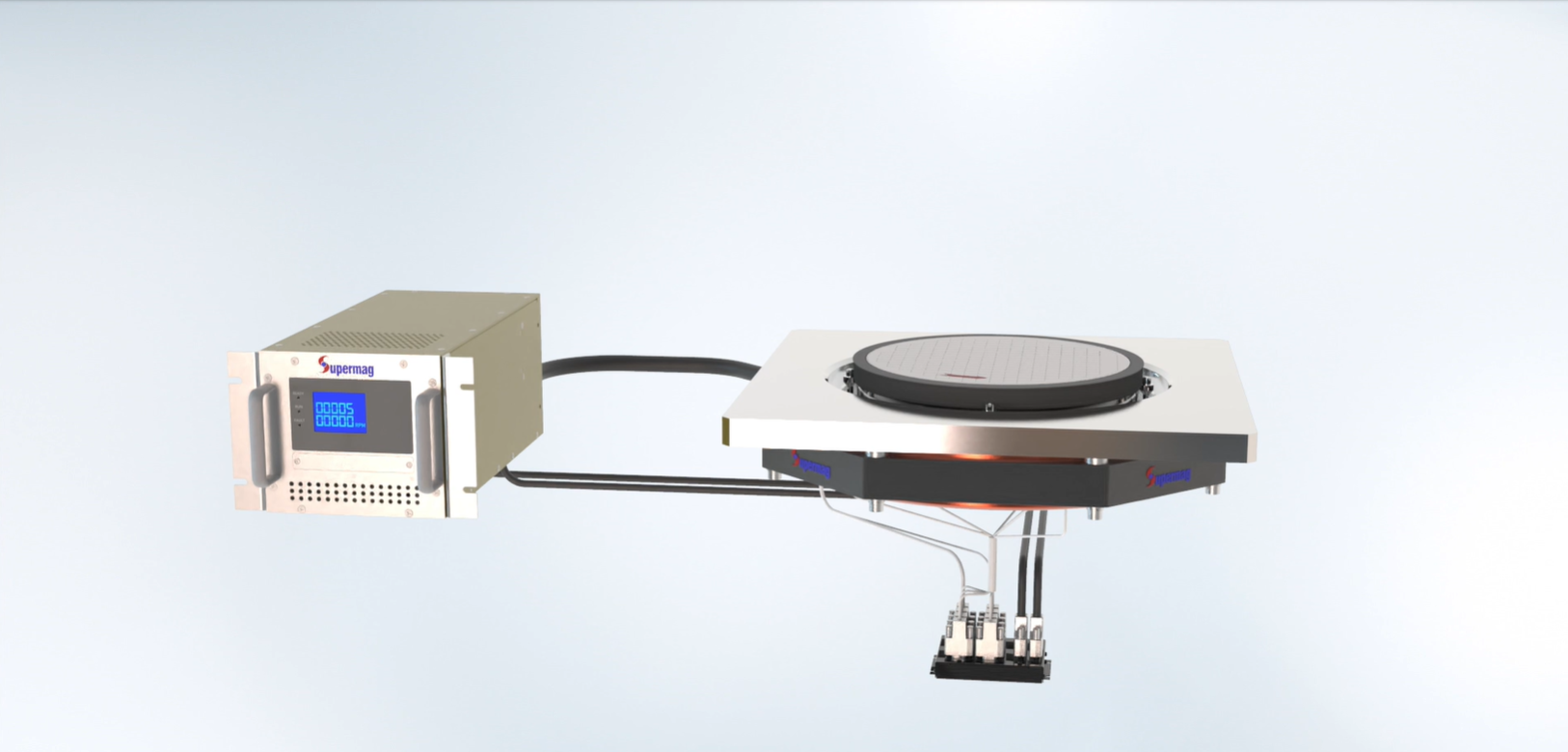

High Cleanliness Rotary Motion

No Mechanical Friction, No Dynamic Seals, No Lubricants Required

Magnetic Levitation Support, Hollow Rotor, Clean and Reliable.

Integrated Magnetic Levitation and Motor Control

Featuring advanced control software, our system supports remote tuning support and seamless communication with upper-level systems such as PLCs and PCs. It is compatible with all Supermag® motor models.

Adjustable Speed and Precise Control

Speed Range: 20-2500 RPM for precise control.

Fully Independently Developed, Customizable

International patents, Customizable to meet semiconductor process requirements.

Auto Zero Position and Adjustable Height

Designed to meet the rigorous demands of semiconductor process inspections.

Compatible with Various Wafer Sizes

Suitable for inspecting 6", 8", and 12" wafers.

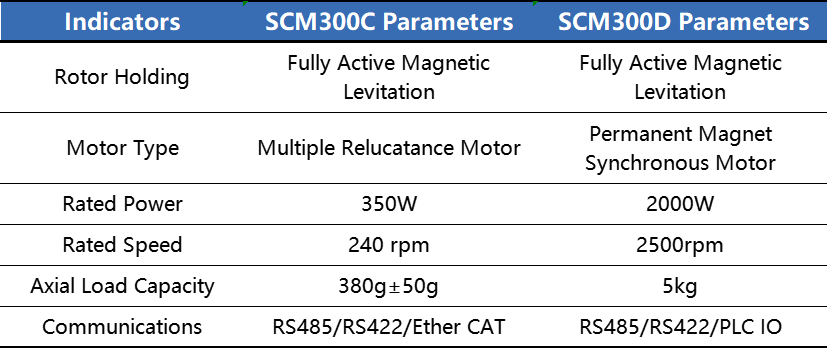

Parameter Specifications:

Product Q&A Videos:

SCM Maglev Wafer Rotation System_Leaflet

Download

Fill in your information